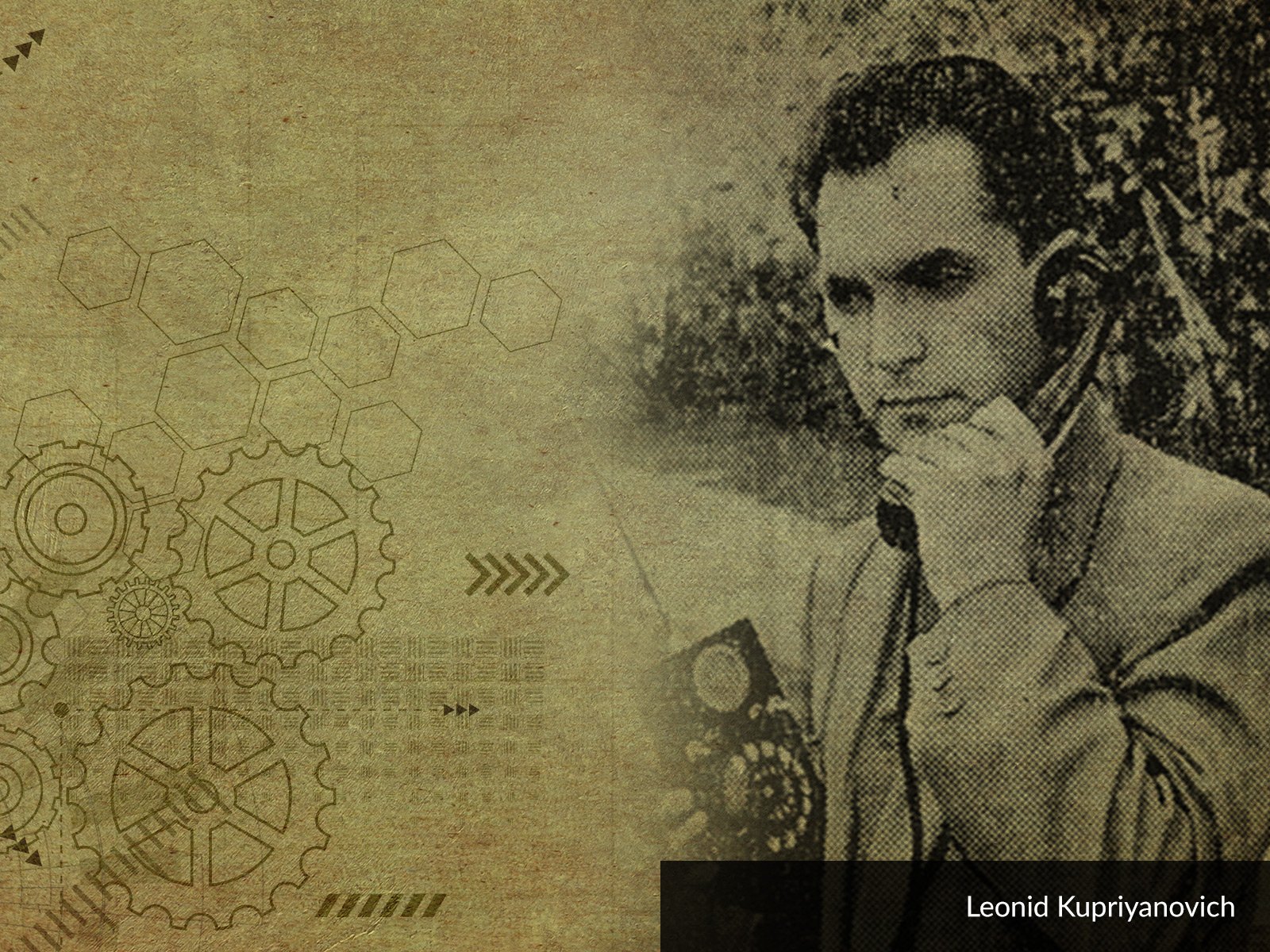

Harry Brearley was born on 18 February 1871. Unlike many other inventors we have described before, he did not have an easy start in life. He was born in Sheffield, England – a town which owes its rapid development to the presence of metallurgical and machine industry. Because of the pollution generated by factories and the poor architecture intended to provide many workers with living space at low cost, George Orwell once called it the ugliest city of the Old World. The Brearleys all lived in a single room. They had a hard time making a living. The father of the future inventor of stainless steel was a steelworker, and the mother would do odd jobs, while also taking care of nine children. Therefore, it is hardly surprising that Harry dropped out of school at the age of 12 in order to start a paid job. He was responsible for, among other things, cleaning the laboratory glassware. His dedication and willingness to learn allowed him not only to support his family financially, but also to acquire knowledge – Brearley took interest in metallurgy and with time became a renowned specialist in this field. In 1908, he was hired to lead Brown Firth Laboratories, a research centre co-financed by two companies from Sheffield.

It was already the time of a growing international tension that later resulted in World War I, so it is not surprising that many of the projects at the Sheffield lab were of military nature. Brearley worked on, among other things, increasing the resistance of steel to high temperatures that were present inside of firearms barrels and accelerated the erosion process. Brearley owes his discovery, one which made his name go down in history, to this very project, coincidence, and his own perceptiveness. The inventor was experimenting with alloys containing chromium, whose properties were meant to improve the quality of steel. He noticed during these experiments that the material he got this way was not only more durable but also much more resistant to corrosive processes. He produced the first alloy of stainless steel in 1913, however the outbreak of the war resulted in the project being put aside. Thankfully, it was not forgotten, and in 1920 the work was resumed. This resulted in, among other things, the popularisation of metal cutlery (before that, cutlery was usually made of much more expensive silver).

Even though his name is not widely known, Harry Brearley’s achievements changed almost every branch of industry. Of course, stainless steel is mostly known as a construction material from the heavy industry, but it is just as often used in the production of precision devices, like measurement tools intended for industrial installations. In the TME catalogue, one can find various enclosures and mechanical elements made from stainless steel. These include bolts, screws, washers, spacers or hinges – these products assure a long service life for the constructed devices thanks to their chemical properties. Brearley’s steel is also a perfect material for the production of tools (wrenches, pliers, screwdrivers etc.) – resistant to factors such as humidity or corrosion, and therefore durable and lasting for years, even in harsh plumbing or field work conditions. Moreover, the alloy developed by the English inventor allows for the production of enclosures that are resistant to mechanical and environmental factors, perfect for the protection of communication and electronic systems mounted on the outside of the buildings.

It is worth noting here that the inventor of stainless steel created The Freshgate Trust Foundation. Its main goal is to financially support local initiatives that are intended to improve the quality of life of people who, just like Harry Brearley, were born into poor families. The foundation funds, among others, educational classes, artistic and sport events, or holiday trips.